Development of new extracts

![]()

Supercritical CO2 extraction makes it possible to obtain new extracts that are hard to be extracted with water.

We entirely support the development of product using the data and know‐how accumulated from the founding of the company in 1900 to the present day.

- Merits of supercritical carbon dioxide (CO2)extraction

- Fat-soluble ingredients (oils and fats, pigment) are usually extracted with organic solvents (hexane, etc.), but the organic solvents remain in the extract, which is considered as a problem. Carbon dioxide is harmless to the human body and can be used as a substitute for the organic extraction solvent. In addition, as the extraction process is performed under an oxygen-free environment with no light, there is no need to worry about oxidation or photolysis of the ingredients.

![]()

| Raw material | Extract | |

|---|---|---|

| Coffee beans, tea leaves | Caffeine (alkaloids) | |

| Hop | α-acids (hop extract) | |

| Tobacco leaves | Nicotine (alkaloids) | |

| Algae | Beta-Carotene, astaxanthin (carotenoids) | |

| Crude propolis | Propolis | |

| Flavor | Vanilla beans | Vanillin |

| Rose | Essential oil (2-phenylethanol) | |

| Lavender | Essential oil (lavender oil) | |

| Jasmine | Essential oil (benzyl acetate, benzyl benzoate, phytol, fatty acid methyl ester) | |

| Peppermint | Essential oil (mint oil) | |

| Peppermint oil | Menthol (fraction: removal of ingredients with unpleasant taste and resin ingredients) | |

| Citrus fruit peel | Citrus oil | |

| Green tea (unfermented tea)、Oolong Tea (half-fermented tea)、Black tea (fermented tea) | Fat-soluble flavor ingredient | |

| Spices | Ginger | Gingerol (pungent ingredient) |

| Red pepper, paprika | Capsaicin (carotenoids) | |

| angelica, allspice, cardamom, sage, celery,caraway, clove,coriander, etc. | Essential oil | |

| Fish oil | EPA、DHA | |

| Turmeric | Essential oil (turmerone: sesquiterpenes), curcumin | |

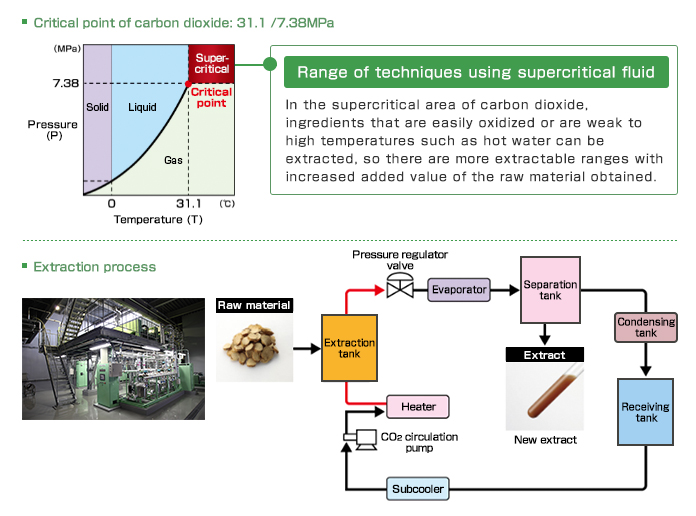

What is supercritical CO2 extraction?

It is an extraction process that uses a CO2 fluid that is beyond the limit (critical point) of temperature and pressure in which gas and liquid can coexist, and has a gas property (diffusion property) of being able to enter anywhere and also a liquid property (solubility) that dissolves ingredients.

Development of new raw materials from extracts and the flow of OEM

Client

Client

meeting- Confirmation of the need for manufacture of product and discussion on the natural product to be extracted per client’s request.

Trial

Trial

production- Trial extraction is conducted using the natural product in question. When using the supercritical CO2 extraction method, we conduct an extraction test using a trial machine that is 1/1000 the size of the actual production machine.

Evaluation

Evaluation- Extracted ingredients obtained from the trial extraction are analyzed and evaluated.

Discussion

Discussion

for actual

production- If the sample extract obtained reaches a high enough level in terms of quality and ingredients, we calculate the cost of actual production and perform a scale-up test using an actual production machine.

Manufacturing

Manufacturing- We determine the extraction conditions based on the result of the scale-up test and manufacture the product

Delivery of the product

Delivery of the product