We are conducting research to identify the best extraction method.

Our company has the best extraction techniques to bring out the features of each

material.

It is possible to create natural extracts with different flavors, active ingredients, and

colors by changing the extraction method even if the same material is used.

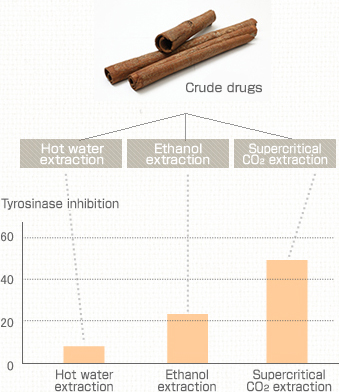

For example, regarding active ingredients, we have physiological activity data from

cinnamon bark that was extracted through various extraction methods. (As shown

below)

The data clearly shows that the activities of the extracts obtained by hot water extraction, ethanol extraction, and supercritical (CO2) extraction are different and that the extract from the supercritical CO2 extraction has the highest activity and is suitable for cosmetics.

The example indicated below shows that when the tyrosinase inhibitory activity was selected and tested, the extract from supercritical CO2 extraction had the highest tyrosinase inhibitory activity, but in some other tests which examined other physiological activities, water extraction was shown to be effective.

We are conducting research to find out the best extraction methods applicable to various

products, so as to be able to say, “XX extract can be used for cosmetics, XX extract for

drinks, and XX extract for food…”

In addition, by changing the extraction method, we can characterize the products not

only from the aspect of active ingredients, but also from the aspects of flavor and color.

Three extraction techniques that bring out the features of materials

Supercritical extraction (supercritical CO2) plant device

This is a plant that performs extraction using supercritical CO2.The supercritical

extraction (CO2 extraction) plant can pressurize up to 50MPa and can primarily extract

hydrophobic ingredients at a highly concentrated level.Supercritical extraction (CO2

extraction) is effective in extracting ingredients sensitive to heat or those that need to

be prevented from oxidizing. This can be done without the use of any residual solvents.

As we have a test machine that is 1/1000 the size of the actual production machine, we

can experimentally perform supercritical extraction (CO2 extraction) using about 100g

of raw material before manufacturing the product.

If you are interested in creating a sample using this test machine before manufacturing

your product, please contact us.

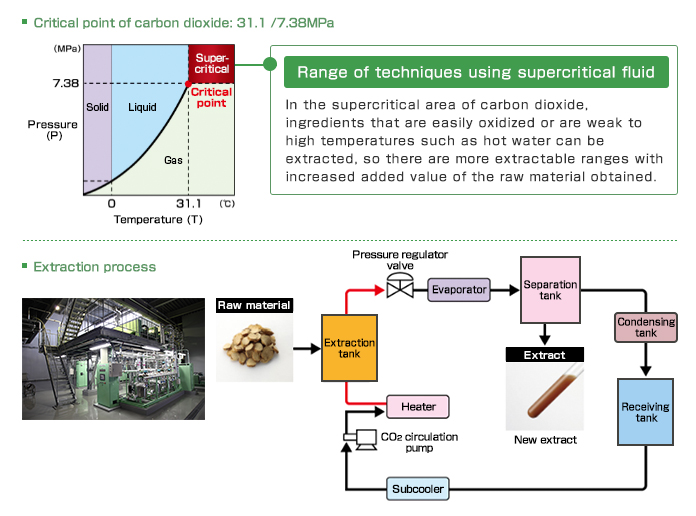

What is supercritical CO2 extraction?

It is an extraction process that uses a CO2 fluid that is beyond the limit (critical point) of temperature and pressure in which gas and liquid can coexist, and has a gas property (diffusion property) of being able to enter anywhere and also a liquid property (solubility) that dissolves ingredients.

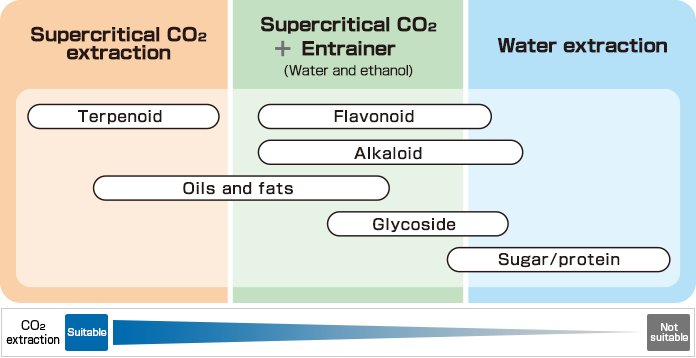

【Characteristics of supercritical CO2 extraction】

Supercritical CO2 has a characteristic of dissolving terpenoids, low-polarity ingredients,

and oils and fats which makes it suitable for extracting these ingredients.

Hydrophilic ingredients that dissolve into water (boiled water) are not suitable to be extracted, but the addition of a small amount of ethanol or water in supercritical CO2

increases the dissolution levels of flavonoids, alkaloids, and glycoside, resulting in it

being possible to obtain the extracts.

Alcohol extraction plant

This is a plant that performs extraction using water-containing ethanol. More lipophilic ingredients are extracted with this extraction method compared to extraction with water only. CIP is used for cleansing.

Hot water extraction plant

This plant performs extraction using hot water. It is used for extraction of Kampo extracts in the manufacture of Kampo products. CIP is used for cleansing.

More about Ominedo’s full-scale production systemMore about Ominedo’s quality management system